Lincoln Nautilus: Roof Sheet Metal Repairs / Roof Side Rail. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Hot Air Gun | |

| Air Body Saw | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

| Flexible Foam Repair 3M™ 08463, LORD Fusor® 121 |

- |

Removal

NOTE: Roof without roof opening panel shown, roof with roof opening panel similar.

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

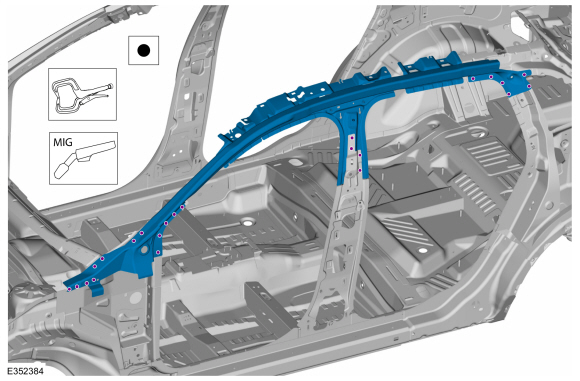

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the side curtain air bag.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Remove the front fender and splash shield.

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the hood.

Refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

-

Remove the front and rear doors.

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

-

Remove the front and rear door hinges.

Refer to: Front Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

-

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Remove the side curtain air bag.

-

Carefully cut the outer panel only.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

.jpg) |

-

Remove the welds

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Pay particular attention to the location of adhesives and sealers to aid in installation.

Remove the body side section.

Use the General Equipment: Hot Air Gun

|

-

Remove the A-Pillar Outer Panel Section and Reinforcement.

Refer to: A-Pillar Outer Panel Section and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Remove the B-Pillar and Reinforcement.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

NOTE: Pay particular attention to the location of adhesives and sealers to aid in installation.

Remove the welds and roof side rail.

Use the General Equipment: Spot Weld Drill Bit

|

Installation

NOTE: Roof without roof opening panel shown, roof with roof opening panel similar.

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Drill plug weld holes.

Use the General Equipment: 8 mm Drill Bit

|

-

Install and weld the B-Pillar and Reinforcement.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Install the B-Pillar and Reinforcement.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the A-Pillar Outer Panel Section and Reinforcement.

Refer to: A-Pillar Outer Panel Section and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Carefully measure and cut the replacement door opening panel to fit the repair and drill plug weld holes.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

Use the General Equipment: 8 mm Drill Bit

|

-

Carefully measure and cut the replacement quarter panel to fit the repair area.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

Use the General Equipment: 8 mm Drill Bit

.jpg) |

-

Install, properly position and clamp the body panel sections.

Use the General Equipment: Locking Pliers

.jpg) |

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

.jpg) |

-

Completely seam weld all sectioning joints.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish all welds as required using typical metal finishing techniques and materials.

-

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Seam Sealing: All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Install NVH foam sealant in areas noted during removal.

Material: Flexible Foam Repair / 3M™ 08463, LORD Fusor® 121

-

Refinish the entire repair using a Ford approved paint system.

-

Remove the following items:

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the side curtain air bag.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the hood.

Refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

-

Install the front and rear door hinges.

Refer to: Front Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

-

Install the front and rear doors.

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

-

Install the front fender and splash shield.

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Align the doors.

Refer to: Front Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

-

Restore corrosion protection.

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Roof Reinforcement. Removal and Installation

Roof Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Other information:

Lincoln Nautilus 2018-2025 Owners Manual: Pre-Collision Assist – Troubleshooting

Pre-Collision Assist – Information Messages Pre-Collision Assist – Frequently Asked Questions Camera Troubleshooting The windshield in front of the camera is dirty or obstructed. Clean the outside of the windshield in front of the camera. The windshield in front of the camera is clean, but the message remains in the instrument cluster display. Wait a short time. It could take several minut..

Lincoln Nautilus 2018-2025 Owners Manual: 911 Assist

How Does 911 Assist Work If a crash deploys an airbag, excluding knee airbags and rear inflatable seatbelts, or activates the fuel pump shut-off, your vehicle may be able to contact emergency services by dialing 911 through a paired and connected Bluetooth-enabled phone. Not all crashes will deploy an airbag or activate the fuel pump shut-off. If a connected cell phone sustains damage or l..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Replacing the Rear Wiper Blades

- Power Outlet - Vehicles With: 110V Power Outlet

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- New on site

- Most important about car

Replacing the Rear Wiper Blades

Note: Do not hold the wiper blade to lift the wiper arm.

Remove the wiper blade.