Lincoln Nautilus: Side Panel Sheet Metal Repairs / A-Pillar Outer Panel. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Hot Air Gun | |

| Air Body Saw | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Restore vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the hood.

Refer to: Hood (501-02) .

-

Remove the front door.

Refer to: Front Door (501-03) .

-

Remove the fender.

Refer to: Fender (501-02) .

-

Remove the hood.

-

Position aside the carpet and wiring.

-

NOTE: Sectioning cutlines shown are intended as a general guideline, depending on vehicle damage.

Determine sectioning point and carefully cut the outer body panel only.

Use the General Equipment: Air Body Saw

.jpg) |

-

Remove the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Use of a heat gun may aid in softening the adhesive.

Remove the panel.

Use the General Equipment: Hot Air Gun

|

Installation

-

Cut section from the replacement panel.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

|

-

Drill holes for plug welding in the replacement part.

Use the General Equipment: 8 mm Drill Bit

|

-

NOTE: Adhesive is applied between the panels and may be resistance welded through.

Apply adhesive as indicated.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

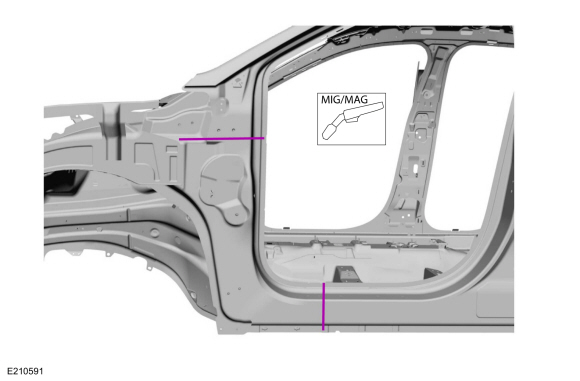

Install and weld the replacement panel.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

|

-

MIG seam weld the replacement panel.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish the repair area using typical repair techniques.

-

Refinish the repair area using a Ford approved paint system.

-

NOTE: Apply seam sealer after priming the area.

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Remove the following items:

-

Install the fender.

Refer to: Fender (501-02) .

-

Install the front door.

Refer to: Front Door (501-03) .

-

Install the hood.

Refer to: Hood (501-02) .

-

Install the fender.

-

Reposition the carpet and wiring.

A-Pillar Outer Panel Section and Reinforcement. Removal and Installation

A-Pillar Outer Panel Section and Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Grinder

Hot Air Gun

Air Body Saw

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam Sealer..

Other information:

Lincoln Nautilus 2018-2025 Service Manual: Cylinder Bore Taper. General Procedures

Check NOTE: Refer to the appropriate Section 303-01 for the specification. Measure the cylinder bore at the top, middle and bottom of piston ring travel in 2 directions as indicated. Verify the cylinder bore is within the wear limit. The difference indicates the cylinder bore taper. If the cylinder bore taper does not meet specification, bore the cylinder to the next oversize lim..

Lincoln Nautilus 2018-2025 Service Manual: Intermediate Shaft. Removal and Installation

Materials Name Specification Motorcraft® MERCON® ULV Automatic Transmission FluidXT-12-QULV WSS-M2C949-A, MERCON® ULV Removal Remove the front halfshaft RH . Refer to: Front Halfshaft RH - 2.0L EcoBoost (184kW/250PS) – MI4, All-Wheel Drive (AWD) (205-04 Front Drive Halfshafts, Removal and Installation). Refer to: Front Halfshaft RH - 2.7L EcoBoost (238k..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Auto Hold

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- Normal Scheduled Maintenance

- New on site

- Most important about car

Changing a Flat Tire

WARNING: If the tire pressure monitor sensor becomes damaged it may not function.

Note: The use of tire sealant may damage your tire pressure monitoring system and should only be used in roadside emergencies. If you must use a sealant, use the Tire Mobility Kit sealant. Replace the tire pressure monitoring system sensor and valve stem on the wheel by an authorized dealer after use of the sealant.

Note: The tire pressure monitoring system indicator light will illuminate when the spare tire is in use. To restore the full function of the monitoring system, all road wheels equipped with tire pressure monitoring sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply the brake hea