Lincoln Nautilus: Rear End Sheet Metal Repairs / Back Panel and Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

| Resistance Spotwelding Equipment |

| Scraper for Straight Edges |

| Grinder |

| Hot Air Gun |

| 8 mm Drill Bit |

| MIG/MAG Welding Equipment |

| Spot Weld Drill Bit |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds. Resistance welds may not be placed directly

over original location. They must be placed adjacent to original

location and match factory welds in quantity. Metal inert gas (MIG) plug

welds must equal factory welds in both location and quantity.

NOTE:

Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Restore the vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the rear bumper.

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

Remove the rear lamp assembly.

Refer to: Rear Lamp Assembly (417-01 Exterior Lighting, Removal and Installation).

-

Remove the loadspace trim panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the liftgate striker.

-

Position the carpeting and the wiring harness away from the working area.

-

Remove the sealer using a grinder with an abrasive disc or equivalent.

Use the General Equipment: Grinder

-

Remove the spot welds on the back panel.

Use the General Equipment: Spot Weld Drill Bit

-

NOTE:

Use of a heat gun may aid in softening the adhesive.

Remove the back panel reinforcement.

Use the General Equipment: Hot Air Gun

-

NOTE:

Use of a heat gun may aid in softening the adhesive.

Remove the liftgate striker.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

On Both Sides:

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

On Both Sides:

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

NOTE:

Pay particular attention to location of sealers and foams used to aid in installation.

Remove the back panel reinforcement.

Installation

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds. Resistance welds may not be placed directly

over original location. They must be placed adjacent to original

location and match factory welds in quantity. Metal inert gas (MIG) plug

welds must equal factory welds in both location and quantity.

NOTE:

Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Drill plug weld holes.

Use the General Equipment: 8 mm Drill Bit

-

Install, properly position and clamp the back panel reinforcement.

Use the General Equipment: Locking Pliers

-

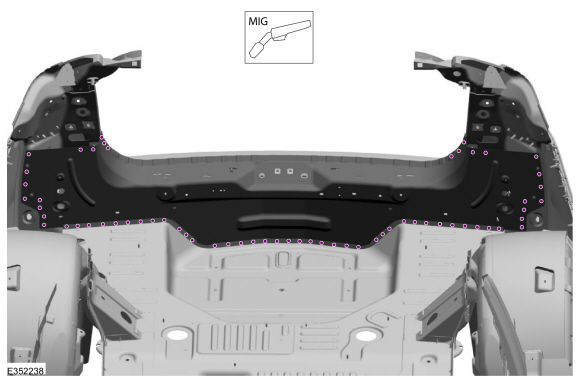

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

On Both Sides:

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

-

On Both Sides:

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Metal finish all welds as necessary using typical metal finishing techniques and materials.

-

Seam Sealing:

All seams must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Drill holes in the replacement part for plug welding.

Use the General Equipment: 8 mm Drill Bit

-

Apply adhesive as indicated.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install the back panel reinforcement and weld.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

-

Finish the repair area using typical metal finishing procedures.

-

Apply sealer at the seams.

-

Sealing work: All areas must be sealed to production level.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Refinish using a Ford approved paint system.

-

Reposition the wiring harness and carpeting.

-

Install the following items:

-

Install the rear bumper.

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

Install the rear lamp assembly.

Refer to: Rear Lamp Assembly (417-01 Exterior Lighting, Removal and Installation).

-

Install the loadspace trim panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Install the liftgate striker.

-

Adjust the liftgate.

Refer to: Liftgate Alignment (501-03 Body Closures, General Procedures).

Special Tool(s) /

General Equipment

Scraper for Straight Edges

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Roof and body side removed for clarity...

Other information:

WARNING: When you install a wheel,

always remove any corrosion, dirt or

foreign materials present on the mounting

surfaces of the wheel or the surface of the

wheel hub, brake drum or brake disc that

contacts the wheel. Make sure to secure

any fasteners that attach the rotor to the

hub so they do not interfere with the

mounting surfaces of the wheel...

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Motorcraft® High Performance Engine RTV SiliconeTA-357

WSE-M4G323-A6

Motorcraft® Silicone Spray LubricantXL-6

ESR-M13P4-A

Permatex® Trim and Weatherstrip Adhesive81850

-

..

Categories

WARNING: If the tire pressure

monitor sensor becomes damaged it may

not function.

Note: The use of tire sealant may damage

your tire pressure monitoring system and

should only be used in roadside

emergencies. If you must use a sealant, use

the Tire Mobility Kit sealant. Replace the tire

pressure monitoring system sensor and

valve stem on the wheel by an authorized

dealer after use of the sealant.

Note: The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply

the brake hea

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Front Floor Panel. Removal and Installation

Front Floor Panel. Removal and Installation