Lincoln Nautilus: Climate Control System - General Information / Heater Core Leak Check. General Procedures

Lincoln Nautilus 2018-2025 Service Manual / Electrical / Climate Control System / Climate Control System - General Information / Heater Core Leak Check. General Procedures

Inspection

-

NOTE: A coolant leak in the heater hose could follow the heater core tube to the heater core and appear as a leak in the heater core.

Inspect for evidence of coolant leakage at the heater hose to heater core attachments.

-

NOTE: Spring-type clamps are installed as original equipment. Installation and overtightening of nonspecified clamps can cause leakage at the heater hose connection and damage the heater core.

Check the integrity of the heater hose clamps.

-

Drain the coolant from the cooling system. Refer to

Cooling System Draining, Filling, and Bleeding procedure in Group 303.

-

Disconnect the heater hoses from the heater core.

-

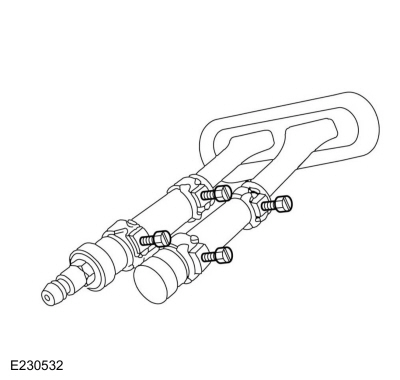

Install a short piece of heater hose, approximately 101 mm (4 in) long on each heater core tube.

-

Fill the heater core and heater hoses with water and

install the plug (221373) and the adapter (221374) from the Pressure

Test Kit. Secure the heater hoses, plug and adapter with hose clamps.

|

-

Attach the pump and gauge assembly from the Pressure Test Kit to the adapter.

-

Access the Pressure Test Kit Service Tools.

Refer to: Climate Control Tools and Equipment (412-00 Climate Control System - General Information, General Procedures).

-

Access the Pressure Test Kit Service Tools.

-

Close the bleed valve at the base of the gauge. Pump 138 kPa (20 psi) of air pressure into the heater core.

-

Observe the pressure gauge for a minimum of 3 minutes.

-

If the pressure drops, check the heater hose connections

to the heater core tubes for leaks. If the heater hoses do not leak,

replace the heater core. Refer to the appropriate heater core removal

and installation procedure in Group 412-00.

Fluorescent Dye Leak Detection. General Procedures

Fluorescent Dye Leak Detection. General Procedures

Leak detection

Review next note for important refrigerant system dye information.

NOTE:

Fluorescent refrigerant system dye is added to the

refrigerant system at the factory to assist in refrigerant system leak

diagnosis using a Rotunda-approved UV

lamp...

Refrigerant Identification Testing. General Procedures

Refrigerant Identification Testing. General Procedures

Activation

NOTE:

Use Refrigerant Identification Equipment to identify

gas samples taken directly from the refrigeration system or storage

containers prior to recovering or charging the refrigerant system...

Other information:

Lincoln Nautilus 2018-2025 Service Manual: Rear Door Moulding. Removal and Installation

Removal NOTE: LH side shown RH side similar. NOTE: Removal steps in this procedure may contain installation details. NOTICE: To avoid damage to the moulding, only use moderate force. Using a non-marring trim removal tool disengage the retainers from the door...

Lincoln Nautilus 2018-2025 Owners Manual: Replacing the Front Wiper Blades. Replacing the Rear Wiper Blades

Replacing the Front Wiper Blades Lift the wiper arm and then press the wiper blade locking buttons together.Note: Do not hold the wiper blade to lift the wiper arm. Note: Make sure that the wiper arm does not spring back against the glass when the wiper blade is not attached...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Power Outlet - Vehicles With: 110V Power Outlet

- Fuel Quality

- Drive Mode Control

- New on site

- Most important about car

Opening and Closing the Hood

Opening the Hood

Copyright © 2025 www.linautilus.com